Overview

We are a group of MTU students who have partnered with a Tech Alum, Tony Senger, to aid him in developing a bicycle hub design that he has patented. The Fall of 2023 team includes 6 mechanical engineering majors: Cade Meyer, Max Maas, Nick Gerstweiler, Caleb Borns, Carter Elmy, and Jack Blake.

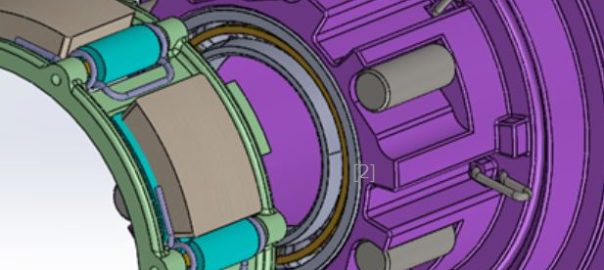

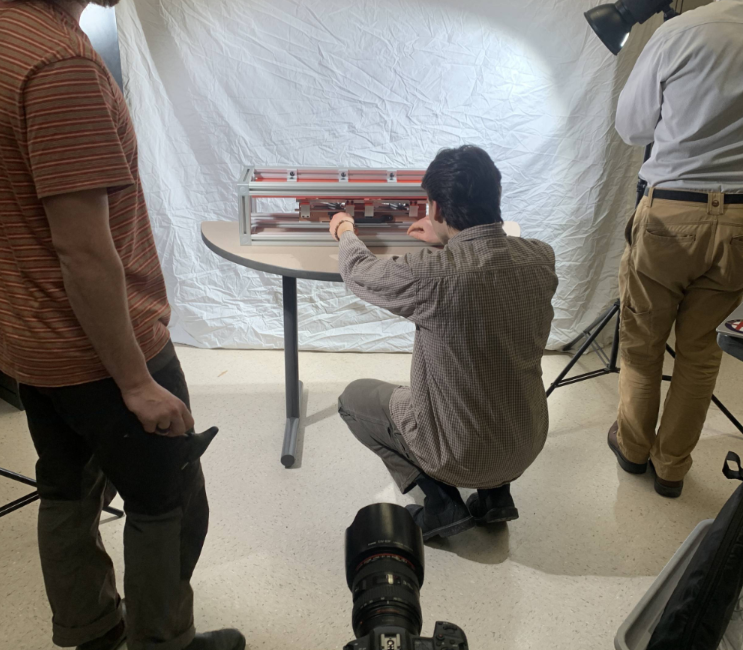

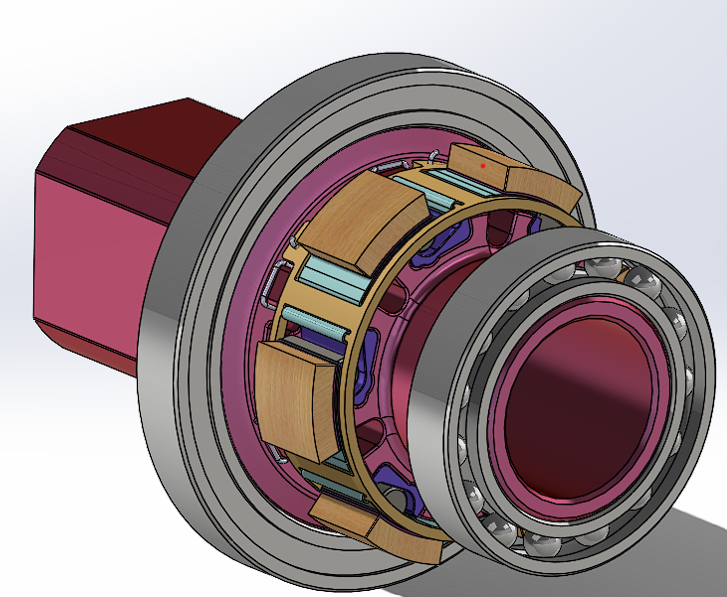

The Senger Innovations LLC Clutch Hub is a new type of hub engagement mechanism designed for bicycle applications to reduce the high frictional drag found in other modern hubs on the market. Anthony Senger approached the Velovations Enterprise of Michigan Tech with a patented roller clutch design looking for assistance in development to one day bring a new low friction hub to the bicycle market. The project saw its initial kick-off in the Spring 2021 semester to break down the hub from its rotational design into a simplified linear model to serve as a proof of concept. We started by creating a multi-body dynamics model in Altair’s Hyperworks MotionView software to complete our simulation. This model was then redesigned for ease of manufacturing and finally transformed into a benchtop sized physical prototype. In the Fall 2022 semester, the team took the benchtop prototype which had excessive friction due to manufacturing and design errors and completely revamped it with many new components and tweaked designs. In the Spring 2022 semester the final version of the benchtop prototype was professionally recorded by a local production company, MONTE. These videos/benchtop model will serve as a tool for Tony to show to investors and interested persons to help explain the technology in the future. The Spring 2022 team also performed structural analysis on multiple different spring configurations options in the radial hub to tune in what materials would best suit the application. Our team has also started developing a DVP&R plan for testing the future prototypes against the competition. We will be building our own testing fixture that can be utilized by future Voodoo Hubs teams. All of our team’s developments are centered around the long-term goal of developing a working hub prototype to provide to Anthony Senger of Senger Innovations LLC.

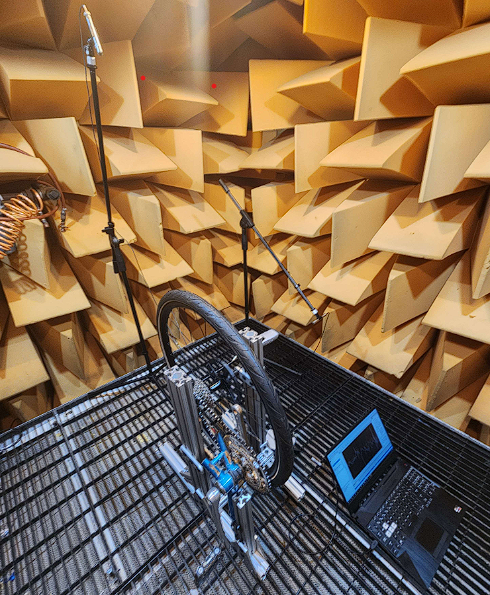

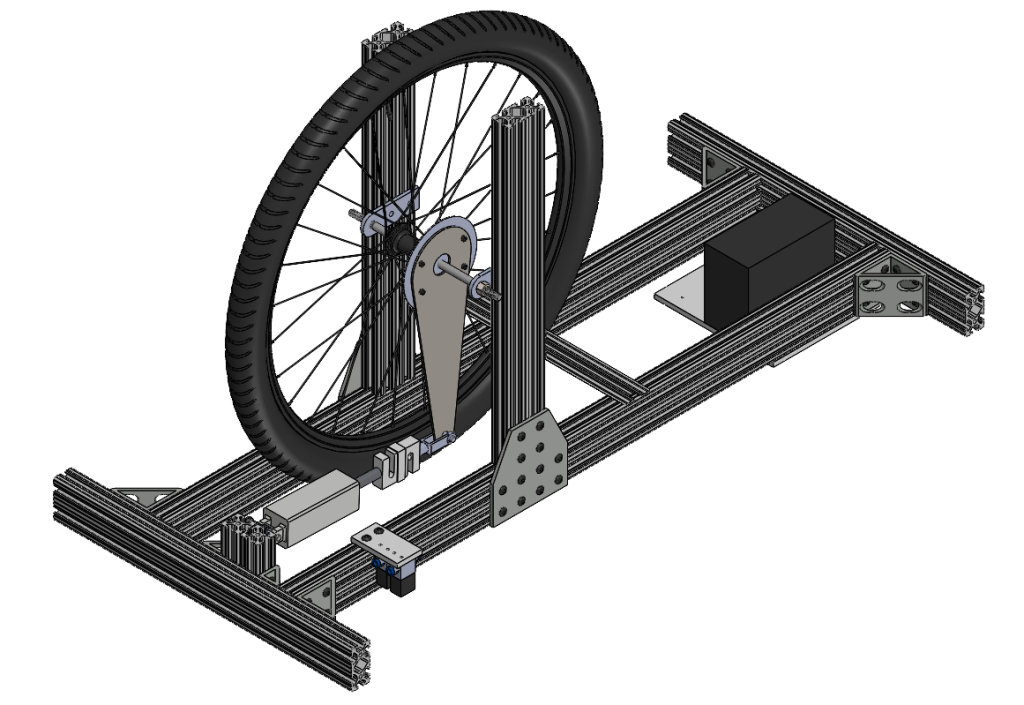

Following our bench top model redesigns and experimental proofing of the systems spring design and force balance we transitioned to a testing systems for the radial hub. This structure change meant we needed to engineer a test stand and testing fixture capable evaluating different competitor hubs to compare to the the voodoo hub. This included a test stand and station set up provided in the figures below was designed for life cycle testing, experimental drag examination, noise analysis, and degrees of engagement. This system will not only help test and compare hubs to one another, but provide pertinent feedback required to improve the design of the Voodooo Hub itself.

Figure XX: Initial frame design of the life cycle test rig.

Figure XX: Initial Hub Prototype

Figure XX: Resistance Application method for life cycle test rig

Figure XX: Resistance Application

Figure XX: Life cycle test rig update

Figure XX: Sound testing in anechoic chamber